MicroCT Basics

Computed tomography is most simply described as 3D X-ray. A hot filament generates an electron beam that is focused by a magnetic lens and reflected off a target (either fixed or rotating) to create X-rays (Bouxsein et al., 2010; Ramsay, 2011). X-ray focal spot size (the region where the beam hits the target) is determined by the amount of energy (in kilovolts [kV]) applied to the filament. These X-rays then travel in a straight line through the object of interest to a detector (Bouxsein et al., 2010; Ramsay, 2011). The object’s attenuation coefficient represents how easily it is penetrated by these X-ray beams. Denser materials absorb more X-rays (higher coefficient), whereas less dense materials absorb fewer X-rays (lower coefficient). The remaining X-rays that pass through the object reach the detector and generate a two-dimensional sample of density differences. The object is rotated a pre-determined number of degrees, and the process is repeated until a complete representation of density variation has been created. Algorithms transform the helical density data into a stack of images, representing a 3D model. The spatial resolution of the resulting model is dependent on the amount of X-ray energy (kV) produced by the equipment, the size of the object under investigation, and its distance from the X-ray source, as well as the size of the detector panel (Ramsay, 2011).

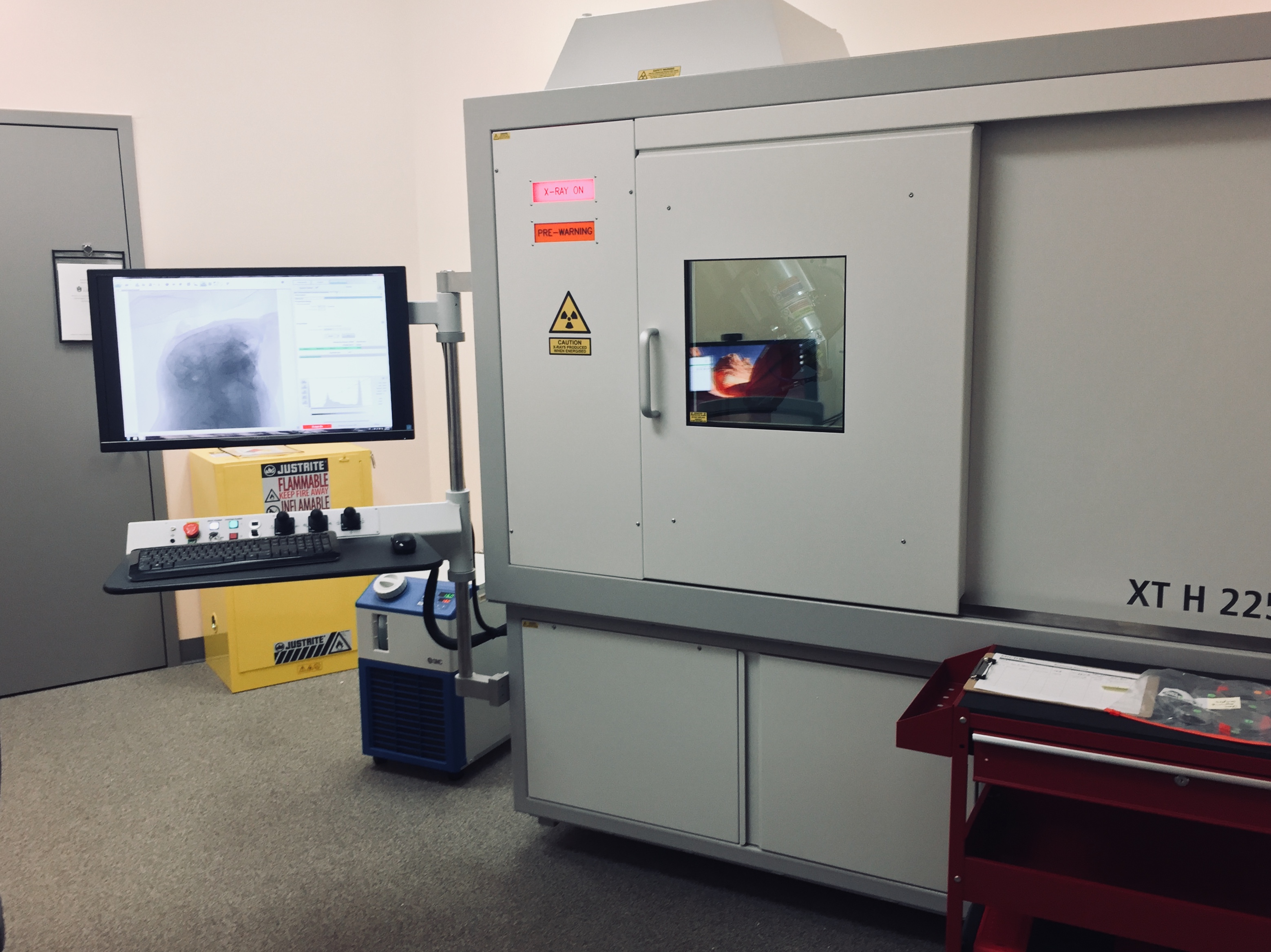

System Specifications

The UArk microCT system is optimized for imaging of a variety of different materials of a range of different densities and sizes. The specific system at the heart of MICRO is a Nikon X TH 225 ST µCT system. This system comes equipped with a 225 kV X-ray tube with a fixed reflection target, which can generate 225 watts (W) of power with a minimum focal spot size of 3 microns (µm). The addition of a 180 kV transmission target (i.e., nano-focus tube) further allows this system to generate a focal spot size of 1 µm and image objects down to the sub-micron level. The MICRO equipment also has a 225 kV rotating target, which makes this system capable of generating up to 450 W of power that can penetrate exceptionally dense materials. With these three interchangeable X-ray sources, this system has the flexibility to image items with voxel resolutions from ~1 µm to 225 µm. The 2000 x 2000 active pixels of the detector panel allow for the examination of objects up to 21 cm in diameter and 50 cm in height, and the maximum sample weight of the system is 50 kg. A motorized detector (i.e., focal spot to imager distance [FID]) enables the rescaling of the system for objects of different sizes in a minimum amount of time, maximizing workflow and reducing individual user costs. The system is fully radiation shielded and generates less than 1 microSievert (µSv) per hour on all external surfaces of the equipment. UAF has a current X-ray license (# CU00004, type XRA11) issued by the Arkansas Department of Health, all µCT users receive X-ray training, and radiation signage is posted in the vicinity of the µCT equipment.

Detailed specifications of the MICRO facility are:

- System Model= Nikon XT H 225 ST

- Cabinet dimensions= 2,424 mm x 1,275 mm x 2,202 mm

- Weight= 4,200 kg

- X-Ray Source (three interchangeable target heads)

- 180 kV transmission target

- Max kV= 180 kV

- Max power= 20 W

- Minimum focal spot size = <1 µm

- Target material= tungsten transmission window

- 225 kV ultrafocus reflection target

- Max kV= 225 kV

- Max power= 225 W

- Minimum focal spot size= 3 µm

- Target material= tungsten or multimetal target (tungsten, copper, molybdenum, or silver)

- 225 kV rotating target

- Max kV= 225 kV

- Max power= 450 W

- Minimum focal spot size = 10 µm

- Sample Manipulator

- Five axis sample manipulator (X,Y,Z, Rotation, Tilt)

- 50 kg maximum weight

- Maximum travel of 450 mm in X, 350 mm in Y, 750 mm in Z

- Precision rotary stage

- Detector

- Perkin Elmer 1620

- 16-bit with 200 µm, 2000 x 2000 active pixels, maximum frame rate= 3.75 frames per second

- Motorized moveable FID (focal spot to imager distance)

- Perkin Elmer 1620

- Onsite Reconstruction PC

- 256 GB RAM

- 2x Deca-Core Intel Xeon processors

- 2x Nvidia graphics cards

- 27” 4K monitor

- Nikon CT Pro 3D reconstruction software

- VGStudio MAX analytical software

- Onsite Data Processing PC

- 256 GB RAM

- 2x Quad-Core Intel Xeon processors

- PNY Quadro Video Card

- Full Avizo/Amira software suite

- 180 kV transmission target

Radiation Safety

The MICRO system is fully radiation shielded and certified by Nikon, the University of Arkansas, and the Arkansas Department of Health (X-ray license # CU00004, type XRA11). The system includes multiple interlocks to ensure that x-rays are not produced when the cabinet door is open. According to the radiation survey conducted in April 2018 (upon installation of the equipment) all radiation readings on the surface of the equipment when the equipment was at full power are <0.03 milliRoentgen per hour, which is roughly equal to 0.026 millirem per hour.

Everyone is exposed to radiation on a regular basis from both natural and human-made sources. This includes background radiation from cosmic sources and naturally occurring radioactive minerals, as well radiation produced by human activities such as nuclear energy, medical imaging, and consumer products. The maximum recommended occupational exposure levels for the whole body (per year) is approximately 5 rem (=5,000 millirem). For comparison, the average cosmic radiation (per year) of someone living at sea level is 0.3 rem and one chest x-ray is equal to 0.1 rem (dose levels taken from the Environmental Protection Agency website). According to the International Atomic Energy Agency, fetal radiation dose should be kept below 1 milliGray (=100 millirad = 100 millirem) during the entire length of the pregnancy. To reach that limit, someone working at MICRO would have to spend over 3,500 hours in the lab during their pregnancy.

You can find more information about radiation exposure at the following links:

References

Bouxsein ML, Boyd SK, Christiansen BA, Guldberg RE, Jepsen KJ, Müller R. 2010. Guidelines for assessment of bone microstructure in rodents using micro-computed tomography. J Bone Min Res 25: 1468-1486.

Ramsay A. 2011. The rules of X-ray micro CT (and when to break them). Quality Mag http://digital.bnpmedia.com/publication/?i=77022&p=86. Accessed December 14, 2015.